Designing Mold Tools for High-Demand Manufacturing

In todays manufacturing landscape, the role of mold tools is indispensable. These tools are the backbone of production, enabling the creation of intricate parts with precision and consistency. Industries such as automotive, electronics, and healthcare rely heavily on mold tools to deliver products that meet the highest standards of quality and efficiency. High precision and repeatability are critical in these sectors, making mold tools an essential component of modern manufacturing.

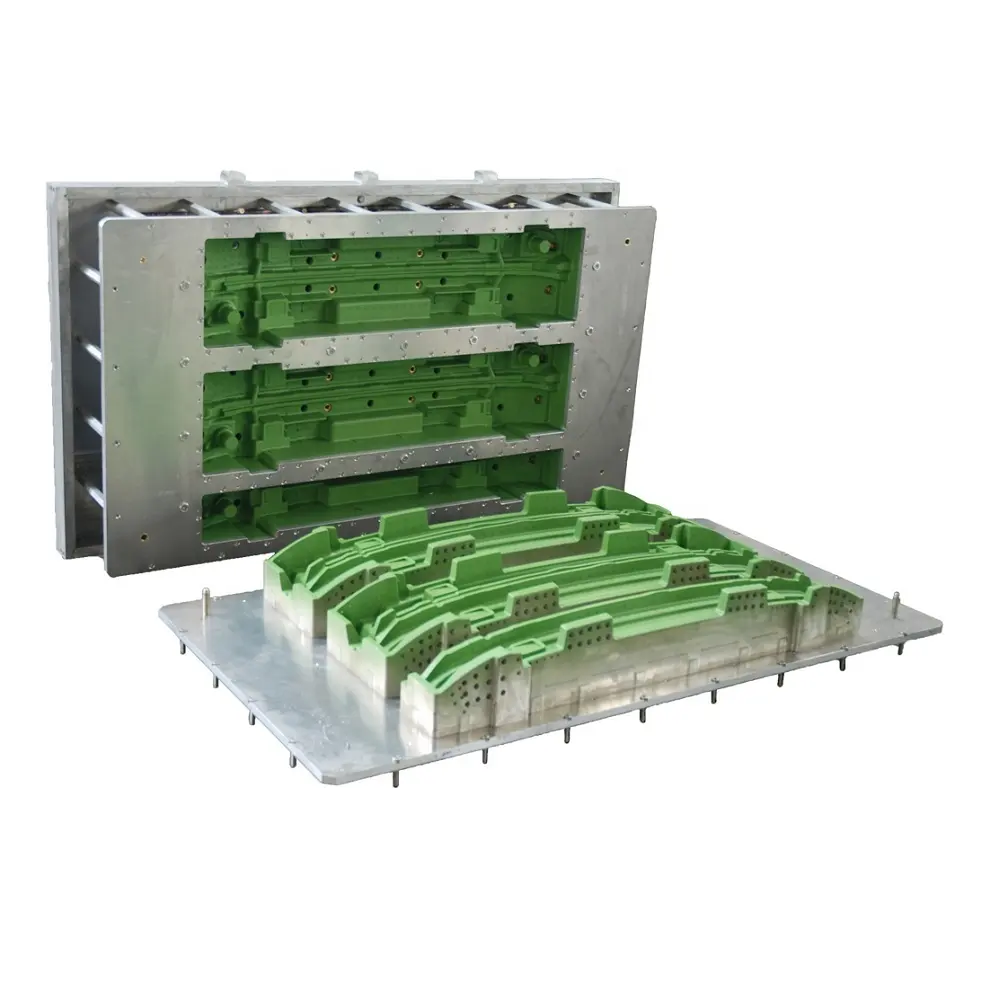

Mold tools are machines designed to shape and mold raw materials into desired forms. They come in various types, each suited for specific applications. For instance, injection molds are commonly used in plastic production, where high precision and repeatability are essential. These molds are typically used to produce intricate and complex plastic parts with a high level of detail. Die casting molds, on the other hand, are ideal for creating metal parts, often used in industries requiring heavy-duty applications. These molds can withstand high pressures and temperatures, producing parts with precise dimensions.

Material Selection for Optimal Mold Tool Performance

The choice of materials for mold tools is critical for ensuring optimal performance. Traditional materials like steel and cast iron, while affordable, have limitations in terms of strength and heat resistance. High-performance materials, such as polypropylene (PPS), polystyrene (PPSU), and polyamide (PA), offer superior performance in high-stress environments. For instance, PPS and PPSU are favored in industries where extreme temperatures are common. Companies like XYZ Plastics use these materials in their injection molds to produce thermoplastics that can withstand harsh conditions. PA, on the other hand, is a popular choice for die casting applications due to its high strength and durability.

Advanced Design Techniques for Precision and Efficiency

Advancements in technology have revolutionized the design and manufacturing of mold tools. Modern design techniques focus on precision, efficiency, and durability. One such technique is 3D printing, which allows for the creation of complex molds with high accuracy. For example, a company like AlphaMolds used 3D printing to develop a highly intricate mold for a new automotive component, significantly reducing the time and cost required for production. Simulation software is another key tool, enabling manufacturers to test and refine designs before committing to production. By simulating the production process, companies like BetaMolds can identify and rectify issues early, ensuring better performance and reduced waste.

Maintenance and Repair Strategies for Mold Tools

Maintenance is a critical aspect of managing mold tools effectively. Over time, mold tools degrade due to wear and tear, which can compromise their performance and lead to costly downtime. Regular maintenance, including cleaning, lubrication, and inspection, helps prevent these issues. For instance, GammaMolds implemented a predictive maintenance strategy using sensors and data analysis. This approach allowed them to predict potential failures and schedule maintenance before any significant issues arose, reducing downtime by 30%.

Real-World Applications of Mold Tool Innovation

The success of mold tool innovation is evident in real-world applications. Companies that have invested in advanced mold tool technology have seen significant improvements in production efficiency and product quality. For example, DeltaMolds upgraded its mold tools to incorporate 3D printing and simulation software. This upgrade resulted in a 20% increase in production capacity and a 15% reduction in material waste. Another case in point is EpsilonMolds, which implemented an AI-driven maintenance system. This system reduced downtime by 30% and improved overall tool longevity.

Future Trends in Mold Tool Design and Technology

The future of mold tool design is poised for significant advancements. Emerging technologies such as Smart Molds, RFID, and AI-driven production are transforming the industry. Smart Molds use embedded sensors to monitor tool performance in real-time, enabling predictive maintenance and optimizing performance. For example, ZetaMolds is already using Smart Molds in their production lines, resulting in a 25% increase in operational efficiency. RFID technology is being used to track mold tools across the production line, improving efficiency and reducing waste. Companies like OmegaMolds are integrating RFID tags into their tooling systems, enabling real-time tracking and inventory management.

Summary and Conclusion

Designing mold tools for high-demand manufacturing is a complex but essential process. From selecting the right materials to implementing advanced design techniques, manufacturers must adopt a strategic approach to ensure the longevity and performance of their mold tools. Regular maintenance and repair strategies, combined with a focus on innovation, are critical for maintaining a competitive edge in todays manufacturing industry. By embracing innovation and staying ahead of emerging trends, companies can deliver high-quality products while maintaining efficiency and sustainability.

In the end, the future of mold tool design promises even greater precision and efficiency. With the right strategies and technologies, manufacturers can overcome the challenges of high-demand manufacturing and achieve excellence in every step of the production process. This innovation not only enhances efficiency but also supports the sustainable practices needed in modern manufacturing.