Innovative Ways to Leverage Proto Molds for Your Designs

Proto molds are temporary molds used to create prototypes, allowing designers to test and refine their ideas quickly and efficiently. Unlike traditional molds, proto molds are often temporary and serve as placeholders to validate concepts before moving to production. They are essential in the early stages of design, enabling teams to iterate and improve without the financial and time investment of creating full-scale prototypes.

The Benefits of Proto Molds: Efficiency and Accuracy

One of the most significant advantages of proto molds is their efficiency. By creating a quick prototype, you can test your design with minimal resources, saving time and money. This is particularly useful in the early stages of development, where iterations are common and costly rework is avoided.

Accuracy is another critical benefit of using proto molds. With precise molds, you can ensure that your final product meets the exact specifications you've outlined. Whether it's a complex mechanical part or a sleek electronic device, proto molds provide the clarity needed to achieve accurate results.

Moreover, proto molds facilitate collaboration between designers and engineers. By creating a shared understanding of the design, they serve as a common ground for communication, reducing misunderstandings and speeding up the development process. This collaborative approach is essential for producing high-quality products that meet customer expectations.

Exploring the Types of Proto Molds: Customization and Specialization

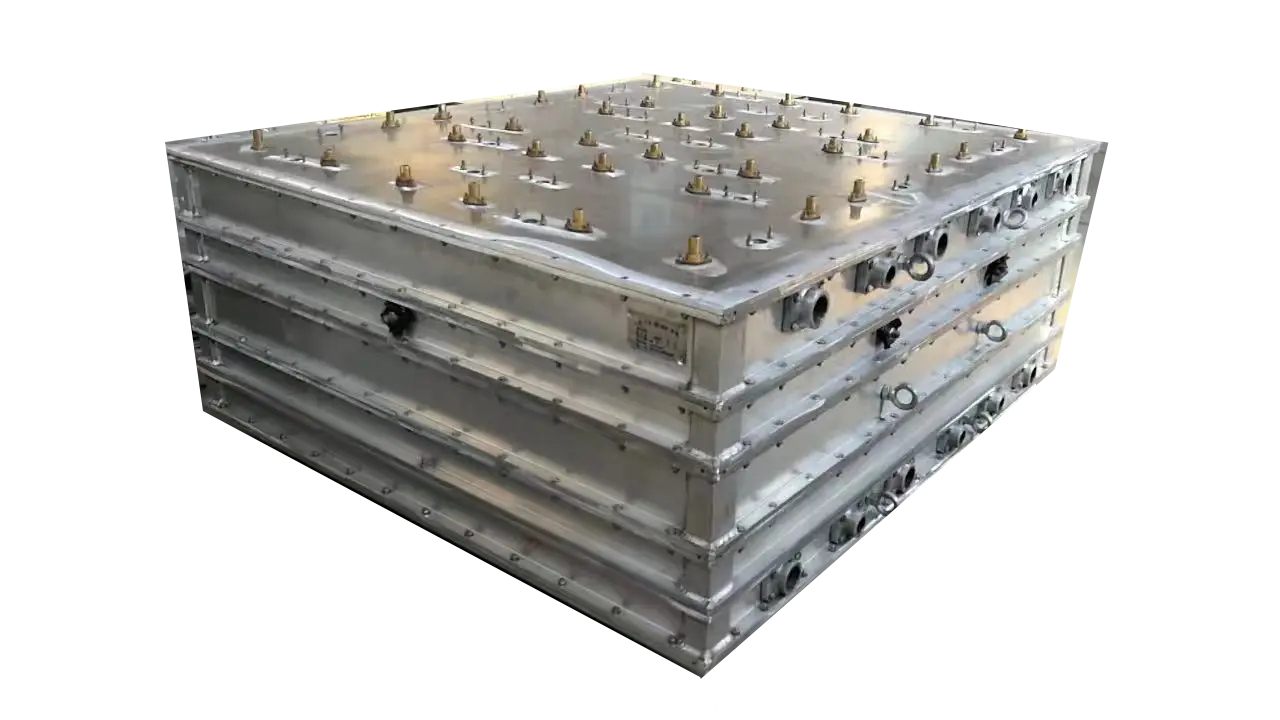

Proto molds come in a variety of forms, each suited for different stages of the design process. Injection molds, for example, are widely used in the manufacturing of plastic parts, offering high precision and durability. Cast molds, on the other hand, are ideal for creating metal components, providing exceptional strength and formability.

3D printed molds represent a cutting-edge innovation, allowing for intricate designs and rapid production. With advancements in additive manufacturing, 3D printed molds are becoming increasingly popular, offering unparalleled flexibility and customization. Each type of proto mold has its unique advantages, making it essential to choose the right one for your project.

The choice of proto mold depends on factors such as material requirements, design complexity, and production capacity. By understanding the strengths and limitations of each type, you can make informed decisions that optimize your design process and deliver high-quality products.

Integrating Proto Molds into Your Design Process

Integrating proto molds into your design process requires a structured approach. Start by identifying the key requirements of your project, such as functionality, aesthetics, and performance. Once you have a clear understanding of your objectives, select the appropriate type of proto mold that aligns with your needs.

The integration process involves several steps, from concept development to production. By collaborating with your team, whether in-house or external, you can ensure that each stage of the process is executed efficiently. Whether youre working on a prototype or a full-scale product, proto molds provide the flexibility and precision needed to achieve your goals.

Success Stories of Proto Molds in Action

The success of proto molds in various industries is a testament to their versatility and effectiveness. From automotive to healthcare, proto molds have been instrumental in driving innovation and delivering high-quality products. Case studies of successful projects highlight the benefits of using proto molds, showcasing how they have enabled teams to overcome challenges and achieve their objectives.

For example, in the automotive industry, proto molds have been used to develop precise and durable components, ensuring that vehicles meet high standards of safety and performance. Similarly, in the healthcare sector, proto molds have played a crucial role in creating custom medical devices tailored to specific patient needs.

These case studies demonstrate the wide-ranging impact of proto molds on product development, providing valuable insights and inspiration for your own projects.

Comparative Analysis: Proto Molds vs. Traditional Molds

When comparing proto molds to traditional molds, its clear that proto molds offer distinct advantages in terms of efficiency, customization, and collaboration. While traditional molds are often used for mass production, proto molds are ideal for early-stage development and rapid prototyping.

One key advantage of proto molds is their versatility. They can be used for a wide range of applications, from simple mechanical parts to complex electronic components. Traditional molds, on the other hand, are typically designed for specific types of products, limiting their adaptability.

Another benefit of proto molds is their cost-effectiveness. By creating a prototype quickly, you can test your design and make necessary adjustments without the need for expensive full-scale production. This approach saves time and resources, allowing you to focus on innovation and development.

The choice between proto molds and traditional molds depends on the specific requirements of your project. Understanding the strengths and limitations of each approach will enable you to make informed decisions that align with your goals and constraints.

Future Trends and Innovations in Proto Molds

The field of proto molds is constantly evolving, with new innovations emerging that promise to revolutionize product design. Advances in 3D printing technology are enabling the creation of even more complex and intricate molds, pushing the boundaries of whats possible in design. Sustainability is another emerging trend, with eco-friendly materials and processes being integrated into the manufacturing of proto molds. By prioritizing environmental responsibility, companies are adopting greener practices that align with global standards and consumer expectations.

Digital mold design and optimization are also gaining traction, with software tools enabling more precise and efficient mold creation. These innovations are enhancing the accuracy and reliability of proto molds, ensuring that they meet the highest standards of quality and performance.

Tips for Effective Use of Proto Molds

To maximize the benefits of proto molds, follow these tips:

1. Start with Clarity: Begin by defining your objectives and requirements, ensuring that your design meets the intended purpose and user needs.

2. Choose the Right Mold: Select a proto mold that aligns with your projects requirements, whether its for injection molding, casting, or 3D printing.

3. Collaborate Effectively: Work closely with your team to ensure that everyone has a shared understanding of the design and requirements, fostering collaboration and reducing misunderstandings.

4. Test and Iterate: Use proto molds to test your design, gather feedback, and make necessary adjustments before committing to production.

5. Adopt Sustainability: Consider eco-friendly materials and processes when creating proto molds, aligning your design with environmental standards and consumer expectations.

By following these tips, you can leverage proto molds to enhance your design process, delivering high-quality products that meet customer needs and industry standards.

Embracing the Future of Proto Molds

Proto molds represent a powerful tool in the arsenal of product designers, offering versatility, efficiency, and innovation in the development process. By understanding their benefits, selecting the appropriate type, and integrating them into your workflow, you can unlock new possibilities and drive your projects to success.

As the field of proto molds continues to evolve, staying informed about the latest trends and innovations will enable you to stay ahead in your industry. By embracing this technology, you can revolutionize your product development process and deliver groundbreaking designs that set new standards in innovation and quality.

Proto molds are not just tools; they are catalysts for change. Embrace their potential and transform your designs for the better.