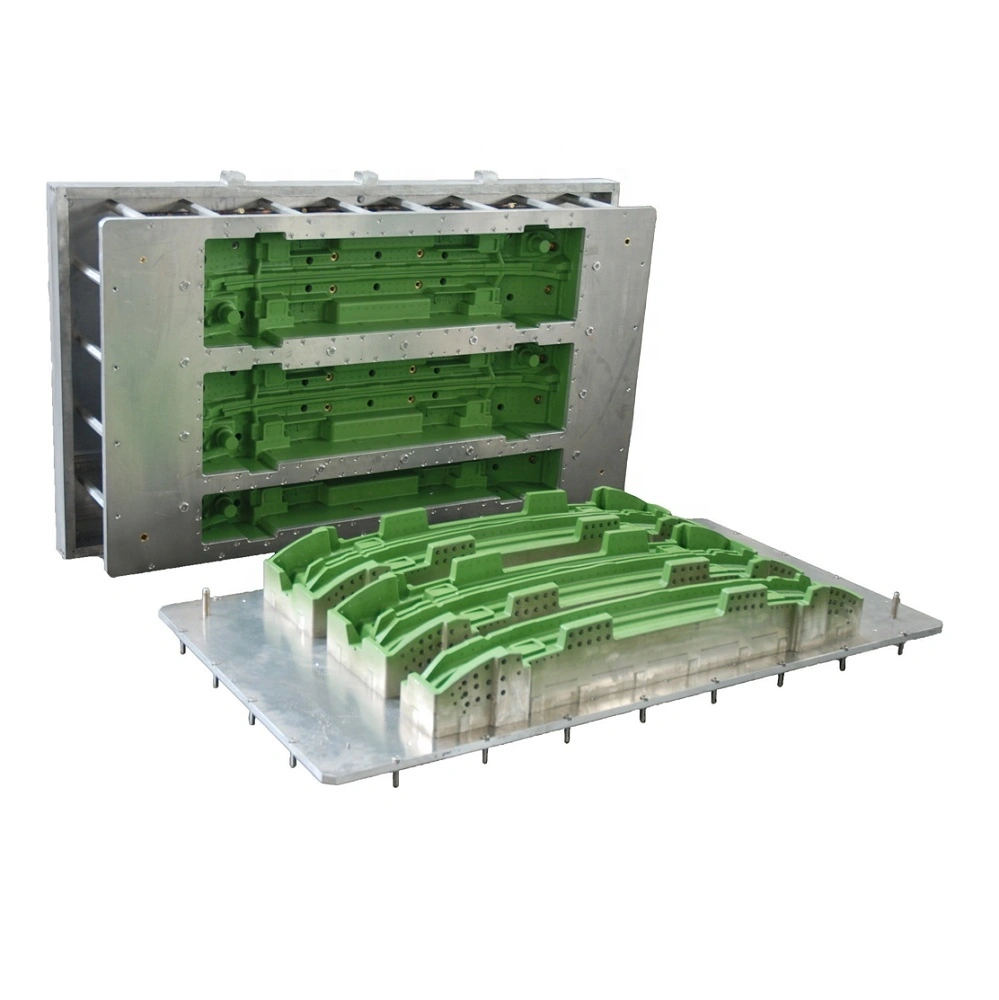

EPP mold

The EPP mold is made of high quality materials including aluminum, copper, and stainless steel for efficient cooling and precision production. It undergoes advanced processing like CNC making and multiple surface treatments to ensure high accuracy and quality products.

Characteristics

1.We supply various of molds and accessories, especially making EPS /EPP mold.

2.The mould applies the high quality aluminum material7075, 6063, 5052, brass copper cooling pipes and spray, filling guns, 304 stainless steel ejectors and screws and so on.

3.The mould with advanced processing, CNC making to keep the high accuracy products. common casting and vacuum casting, sandblast, several layers of Teflon painting and lighting.

4. We have 30 years experience for making all kinds of the EPS/EPP mold tools and the customers are from around the world.

5. Fast working process and short cycle time, Saving energy and high efficiency working capacity.

6. The molds made by more thickness and better quality aluminum plates, and stronger mold structure for high efficient working capacity and longer working life.

7. Material name and grade of all parts of each die as followings:

Steam chamber:AL NO.: 7075,6063

Four Al plates :AL NO.: 7075,6061T, 5052

Cavities : AL NO.:A356.2

Water cooling pipe:Red copper, water spray nozzles: brass

Screws:SS304, Holders: copper brass

Teflon coating: Japan Daikin brand----Primer coat:EK-1909S-602L, Top coat:EK-3798M-650L

Why Choose EPP Mold?

1. Superior Material Properties:

- Lightweight yet Strong: EPP is renowned for its exceptional strength-to-weight ratio, making it ideal for products that require robust performance without the added weight.

- Thermal Resistance: EPP can withstand extreme temperatures, ensuring your products maintain integrity under various conditions.

- Impact Resistance: EPP moulded products can absorb significant energy from impacts, enhancing the safety and durability of your items.

2. Cost-Efficiency:

- Reduced Material Waste: The moulding process for EPP is highly efficient, minimizing material waste and reducing overall production costs.

- Lower Shipping Costs: The lightweight nature of EPP translates to lower transportation costs, saving you money on logistics.

3. Environmental Sustainability:

- Recyclable: EPP is 100% recyclable, aligning with global sustainability goals and reducing your environmental footprint.

- Energy-Efficient Production: The energy requirements for EPP moulding are lower compared to other materials, further enhancing your eco-friendly credentials.

4. Versatility in Application:

- Diverse Industry Use: EPP molds are used across various industries, including automotive, packaging, consumer goods, and more.

- Customization Solutions: EPP molds can be tailored to meet specific design and functional requirements, providing you with bespoke solutions for your unique needs. Don't let your competitors get ahead. Embrace the future of manufacturing with EPP moulding and experience the transformative benefits it brings. Our team of experts is ready to assist you in integrating EPP mould technology into your production process.

Function And Application

It will be installed and run on the EPS/EPP shape molding machine to produce all kinds of packaging and insulation products such as Car parts, toys, seafood/fruit/vegetable/ice boxes, packing products, tools, decoration, cold storage, ICF constructions and Appliances inner parts and so on.