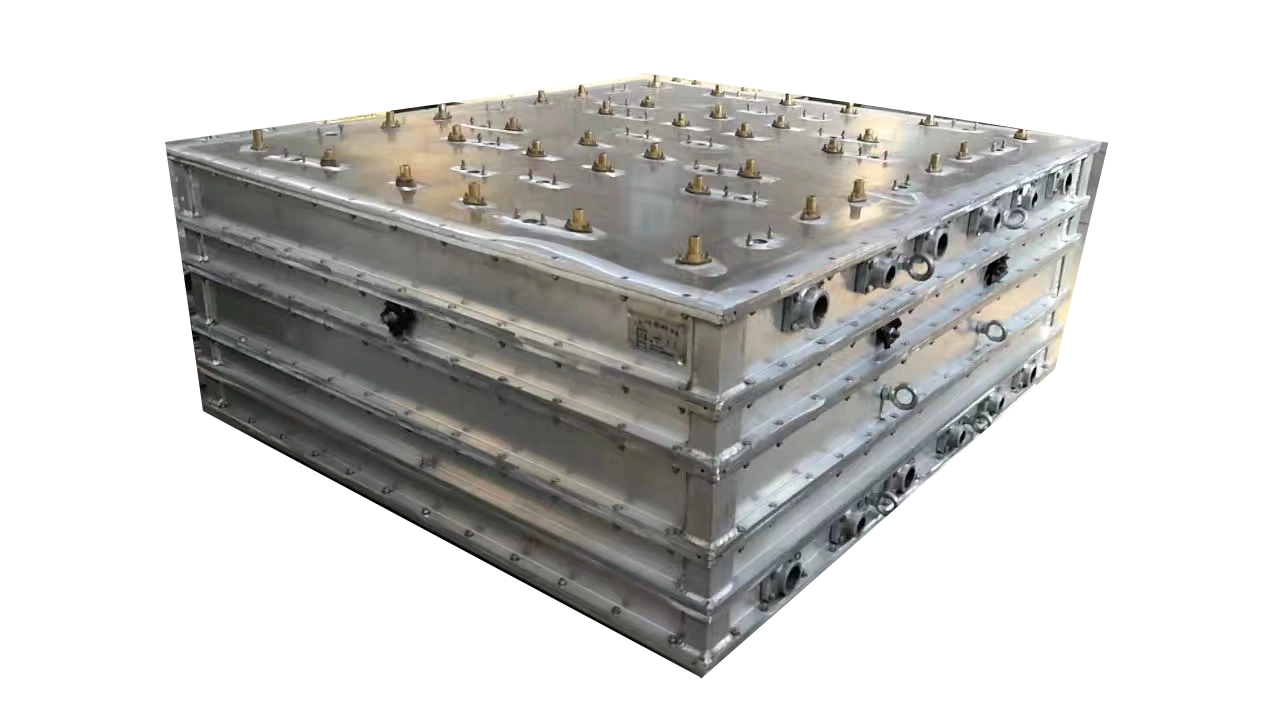

EPS mold

The EPS mold is made with high-quality materials like aluminum, copper, and stainless steel for precision and durability. Its advanced processing techniques ensure high accuracy products with various casting and painting options available.

Characteristics

1. We supply various of molds and accessories, especially making EPS /EPP mold.

2. The mould applies the high quality aluminum material7075, 6063, 5052, brass copper cooling pipes and spray, filling guns, 304 stainless steel ejectors and screws and so on.

3. The mould with advanced processing, CNC making to keep the high accuracy products. common casting and vacuum casting, sandblast, several layers of Teflon painting and lighting.

4. We have 30 years experience for making all kinds of the EPS/EPP mold tools and the customers are from around the world.

5. Fast working process and short cycle time, Saving energy and high efficiency working capacity.

6. The molds made by more thickness and better quality aluminum plates, and stronger mold structure for high efficient working capacity and longer working life.

7. Material name and grade of all parts of each die as followings:

Steam chamber: AL NO.: 7075,6063

Four Al plates: AL NO.: 7075,6061T, 5052

Cavities: AL NO.:A356.2

Water cooling pipe:Red copper, water spray nozzles: brass

Screws: SS304, Holders: copper brass

Teflon coating: Japan Daikin brand----Primer coat:EK-1909S-602L, Top coat:EK-3798M-650L

Advantages

1.Exceptional Precision: EPS molds offer high dimensional accuracy, ensuring that your products meet exact specifications.

2.Cost-Effective: Reduce production costs with durable and reusable molds that provide consistent quality over time.

3.Versatile Applications: Ideal for a wide range of industries including packaging, construction, automotive, and more.

4.Eco-Friendly: EPS is recyclable, contributing to sustainable production practices and reducing environmental impact.

5.Custom Design: Tailored to meet your specific needs, our design team works with you to create molds that optimize your production process.

6.High-Quality Materials: We use the best EPS materials to ensure durability and performance.

Expert Support: From concept to completion, our experts provide guidance and support to help you achieve the best results.

Mold Example

Box mold

Decoration cornnies mold

Hemlet mold

ICF mold

Mold 3d structure

Packaging mold

Function And Application

EPS molds will be installed and run on the EPS/EPP shape molding machine to produce all kinds of packaging and insulation products such as seafood/fruit/vegetable/ice boxes, packing products, tools, decoration, cold storage, ICF constructions, cars and Appliances inner parts and so on.

EPS molds are essential tools used in the manufacturing process of Expanded Polystyrene (EPS) products.These EPS molds are designed to shape and form EPS beads into various shapes and sizes, creating a wide range of products from packaging materials to insulation panels and architectural elements.

Packaging: All kinds of Boxes, trays, and protective packaging for electronics, appliances, and other products.

Construction: ICF products, Insulation panels, architectural elements, and decorative moldings.

Automotive: Bumpers, interior components, and packaging materials.

Consumer goods: Cups, plates, and other disposable items.

Industrial applications: Flotation devices, insulation for pipes and tanks, and protective covers.