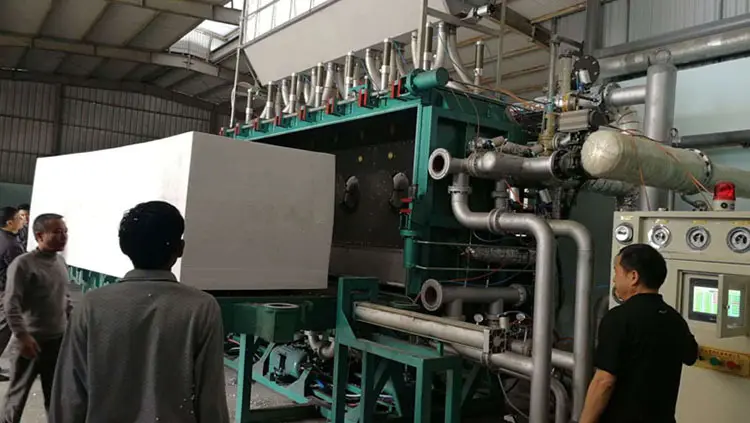

Fine Quality Eps Compactor Machine From China

Product details of the eps compactor machine

Product Overview

The unique function of eps compactor machine is well received by the customers. The product is unmatched in performance, service life and usability. We will pack the eps compactor machine with the high quality materials to ensure the safety.

Product Description

Compared with ordinary products, our eps compactor machine has the specific differences as follows.

Characteristics

Adjustable Thermocol EPS Block Molding Machine

Control System

PLC and human-touch Control, electrical controller and computer control system are available.

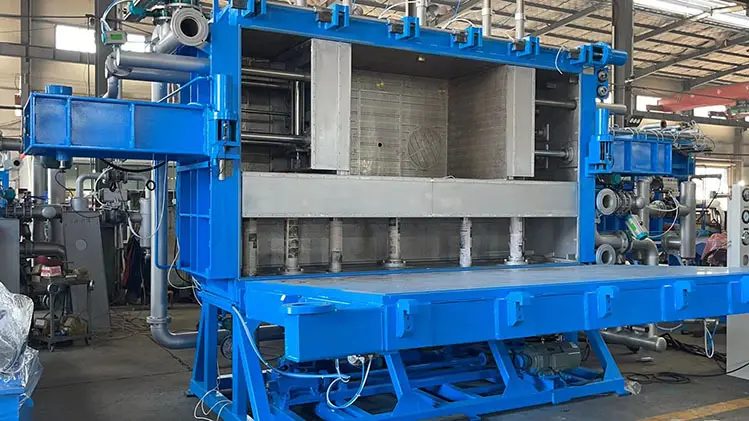

Structure Design

High quality square tube and steel plate are used for the machine’s structure in perfect strength without deformation.

Hydraulic station control the signal door, model’s stripping, and locking device.

Spare parts and fittings are high quality products of well-known brand which keep the machine in a long service life.

Processes

Automatic pneumatic feeding and fan feeding methods

Heat treatment, material feeding

Production Efficiency

Fast cooling speed and low cost.

High production efficiency: a light board only takes 2-3min.

Products with low moisture content and stable size

Energy saving

Technical Data

| ITEM | Unit | SPB2000V | SPB3000V | SPB4000V | SPB6000V | |

| Mould Size | mm | 2050*1240*630 | 3080*1240*630 | 4080*1240*1030 | 6080*1240*1030 | |

| Block Size | mm | 2000*1000*500 | 3000*1200*600 | 4000*1200*1000 | 6000*1200*1000 | |

| Steam | Consumption | kg | 18~25 | 55~65 | 60~85 | 95~120 |

| Pressure | Mpa | 0.6~0.8 | ||||

| Compressed air | Consumption | M3 | 1~1.2 | 2~2.2 | 1.8~2.5 | 2~3 |

| Pressure | Mpa | 0.6~0.8 | ||||

| Vacuum cooling water | Entry | mm | DN40 | DN40 | DN40 | DN40 |

| Consumption | m3/cycle | 0.4 | 0.6 | 0.8 | 1 | |

| Pressure | Mpa | 0.2-0.4 | 0.2-0.4 | 0.2~0.4 | 0.2~0.4 | |

| Drainage | Vacuum drain | mm | DN100 | DN125 | DN125 | DN150 |

| Down drain | mm | DN10 | DN150 | DN150 | DN150 | |

| Fan drain vent | mm | DN100 | DN150 | DN150 | DN150 | |

| Capacity @15kg/m3 | min/cycle | 10 | 15 | 7 | 8 | |

| Connected Power | KW | 7 | 9.5 | 24.5 | 32.25 | |

Advantages

1. High Quality EPS Foam Block Moulding Machine Fully automatic working by computer control system with PLC and color touch screen.

2. Fastest working process and shortest cycle time, Saving energy and biggest capacity.

3. Germany technology and pipe control system, it can make the lowest and highest density from 4g/l to 50g/l block, the best quality and most popular block machine.

4. It can adjust the block size, with bigger feeding system and safety lock control system.

5. The machine made by more thickness steel plates, bigger pipes &valves and stronger machine structure for high efficient working capacity and long working life.

6. Excellent machine design with easy installation,operation and maintenance, good welding and painting, beautiful appearance of the complete machine.

7. Have vacuum and air cooling system, horizontal and vertical types.

8. The machine can adjust the block mould size to get different size of the EPS block products.

Detail Of Key Parts

Function And Application

It used to produce EPS blocks for building construction, packing products and other insulation products such as EPS sandwich panel of wall and roof, packing furniture/glasses, tools, CNC cutting products, decoration, cold storage house and so on.

Company Information

Hangzhou Minglong Technology Co.,Ltd is a company located in We concentrate on the production and sales of EPS machine, EPP machine. Our company thinks highly of service. We innovate service methods and improve service quality, so as to provide thoughtful services for each customer, including pre-sales consulting, after-sales service management. Look forward to working with you to create a better future.