Cnc Eps Foam Cutting Machine Wholesale - Minglong

Characteristics

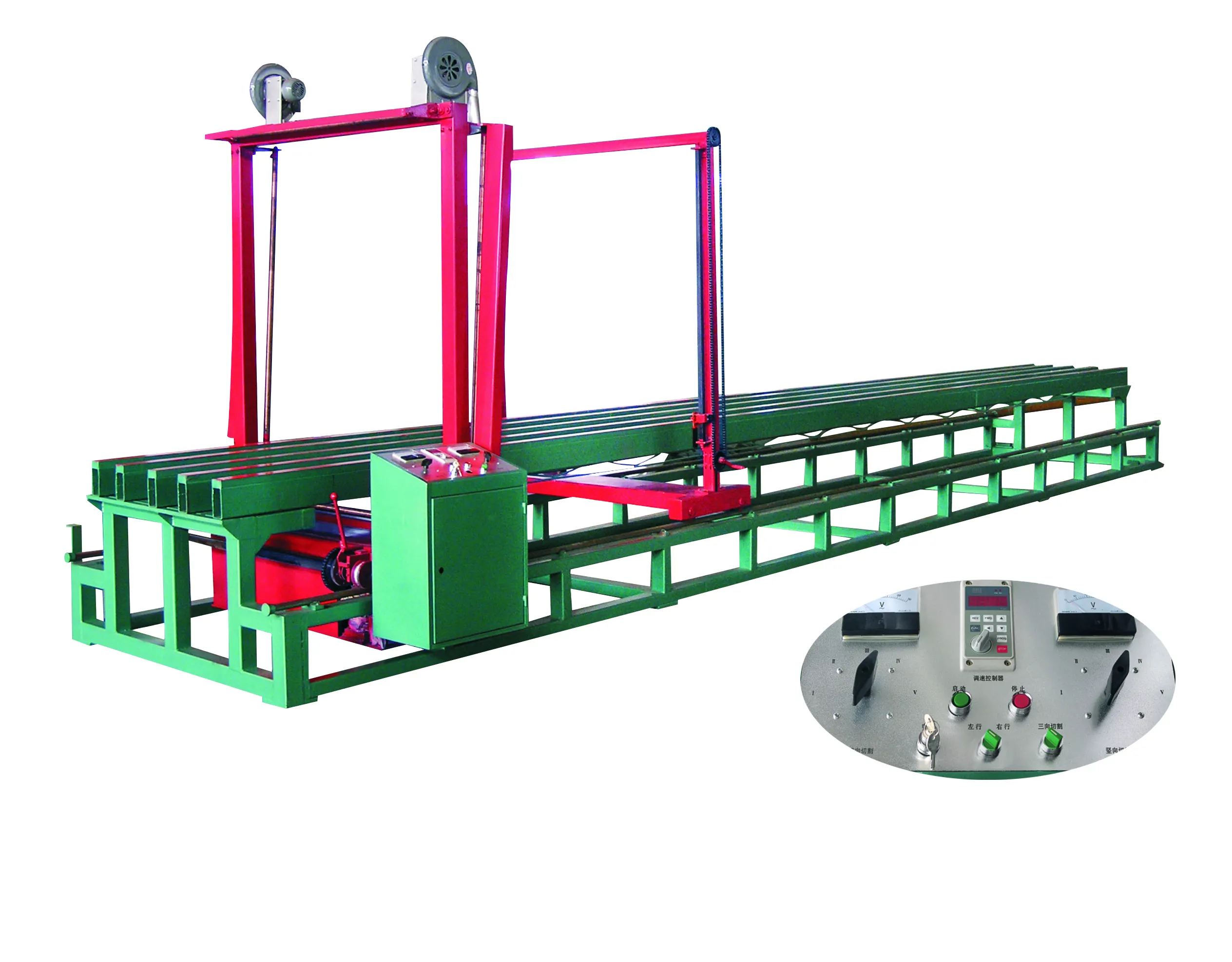

1. This machine can use for straight line cutting with three cutting direction: horizontal, portrait and vertical cutting, it can realize.

2 direction cutting at the same time which improves production efficiency. It is suitable for block cutting. It can also 2D and 3D cutting by computer design drawing for different kinds of shape forming instead of molds, which can save the cost of molds and promote efficiency.

3. This machine applies converter speed governing, which makes stable moving, and large range of step-less speed governing accordingly. Guide-rail drive makes cutting trim and flat. It applies motor-decelerator integrating system, which lowers the noise, has high practical value.

4. It applies two transformers and large power transformer, which promote the speed of cutting and lengthen service life.

5. This machine applies cutting retract device, which can shorten 3-10 mins when reposition.

6. This machine applies multi-wire cross cutting setting, which can cut the block to 3 to 5mm thin sheets.

7. There is the type of the continuous cutting machine controlled by the computer system.

Technical Data

TYPE B

| ITEM | Unit | DSQ-2000B | DSQ-4000B | DSQ-6000B | |

| Max Cutting Size | mm | 2000*1250*1300 | 4000*1250*1300 | 6000*1250*1300 | |

| Heating Wires Amount | Horizontal | pcs | 80 | 80 | 80 |

| Portrait | pcs | 30 | 30 | 30 | |

| Vertical | pcs | 1 | 1 | 1 | |

| Working Speed | m/min | 0~1.8 | 0~1.8 | 0~1.8 | |

| Connected Load | kw | 21 | 21 | 21 | |

| Overall Dimension | mm | 4800*1900*2500 | 6800*1900*2500 | 8800*1900*2500 | |

| Weight | kg | 1000 | 1800 | 2200 | |

TYPE C

| ITEM | Unit | DSQ-3000C | DSQ-4000C | DSQ-6000C | |

| Max Cutting Size | mm | 3000*1250*1250 | 4000*1250*1250 | 6000*1250*1250 | |

| Heating Wires Amount | Horizontal | pcs | 60 | 60 | 60 |

| Portrait | pcs | 60 | 60 | 60 | |

| Vertical | pcs | 20 | 20 | 20 | |

| Working Speed | m/min | 0~2 | 0~2 | 0~2 | |

| Connected Load | kw | 35 | 35 | 35 | |

| Overall Dimension | mm | 5800*2300*2600 | 6800*2300*2600 | 8800*2300*2600 | |

| Weight | kg | 2000 | 2500 | 3000 | |

Advantages

1. It has three ways cutting direction: Horizontal, portrait, vertical.

2. It can fix 100 cutting wires at same time and cut different size of the products.

3. It can cut in two direction automatically at the same with many wires for high capacity.

4. It can cut in strait line and 3D CNC cutting for all kinds of the products.

5. Excellent machine design with easy installation,operation and maintenance, good welding and painting, beautiful appearance of the complete machine.

6. It can be continuous cutting and controlled by the computer system.

Function And Application

It used for cutting EPS blocks into different size and shapes for building construction, packing products and other insulation products such as EPS sandwich panel of wall and roof, packing furniture/glasses, tools, CNC cutting products, decoration, cold storage house and so on.

Company Advantages

· Hangzhou Minglong Technology Co.,Ltd is not only a pioneer in technology, but also forgoer in developing new cnc eps foam cutting machine.

· The fully trained and qualified QC team is responsible for the quality of this product.

· The assurance of cnc eps foam cutting machine will contribute to the development of Minglong.

Company Features

· Hangzhou Minglong Technology Co.,Ltd, whose technology is introduced from abroad, is a leading firm in field of cnc eps foam cutting machine.

· Advanced equipment together with our staff’s stringent working ethic has reduced the reject ratio of our products lower than 0.0006%.

· Hangzhou Minglong Technology Co.,Ltd is striving for world-class cnc eps foam cutting machine supplier. Get quote!

Application of the Product

Minglong's cnc eps foam cutting machine can play a role in various industries.

We have been engaged in the production and management of EPS machine, EPP machine for many years. For some problems encountered by customers in the procurement, we have the ability to provide customers with a practical and effective solution to help customers solve problems better.