Newest Eps Crusher Price List

Product details of the eps crusher

Quick Overview

Minglong eps crusher is made from the best quality raw materials. The quality of the product has been effectively improving. Minglong's eps crusher can be used in multiple industries. With the annual sale volume ranking first in the industry, the product is believed to be used by more people in the future.

Product Introduction

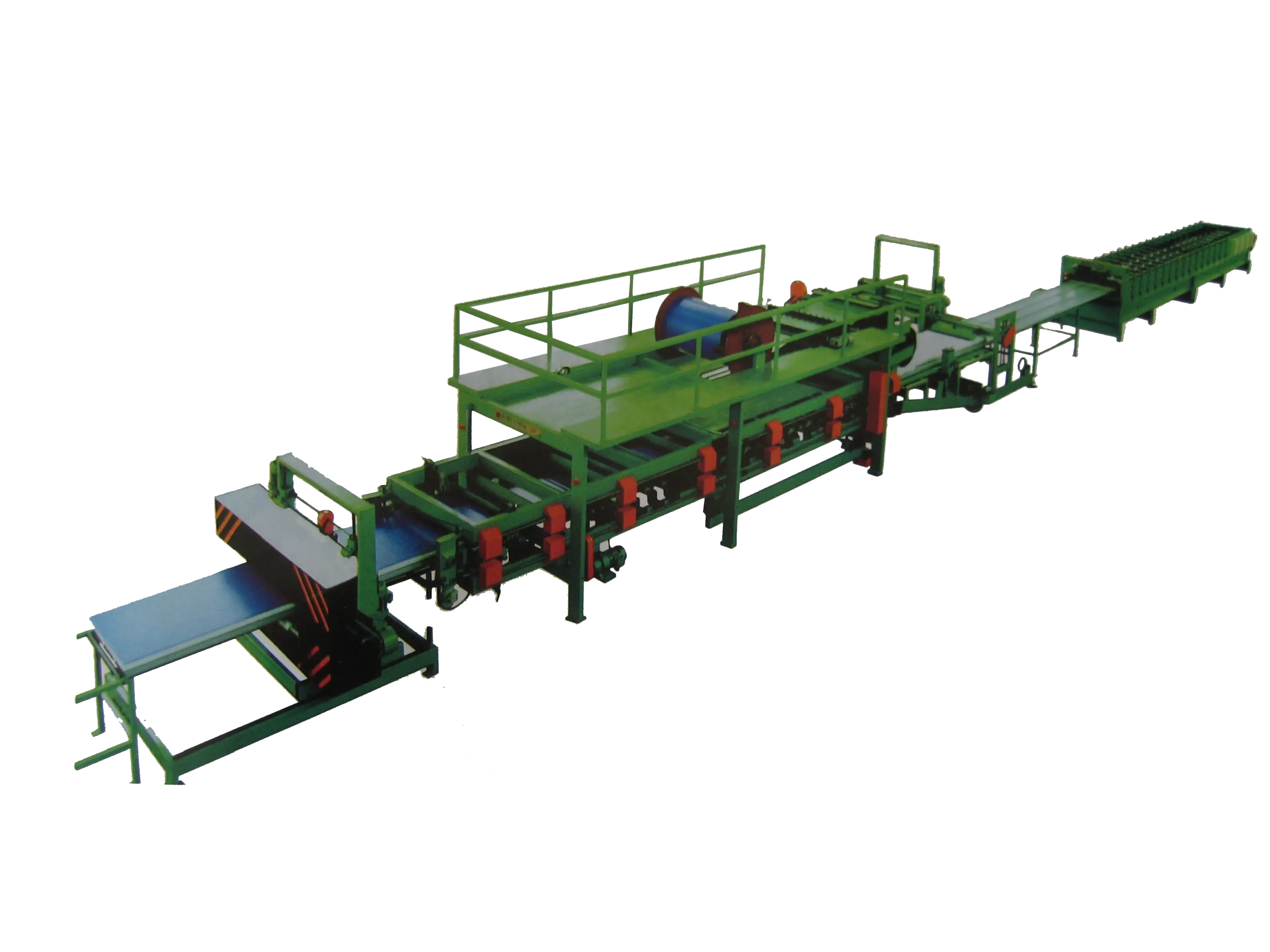

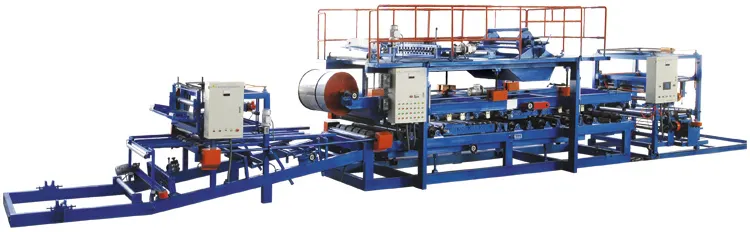

The eps crusher produced by Minglong has better quality, as shown below.

Characteristics

1. EPS sandwich panel machine is a specialized manufacturing equipment used to produce sandwich panels, which consist of a core material (such as Expanded Polystyrene – EPS) sandwiched between two outer layers of material (typically steel sheets or aluminum sheets). These panels are widely used in construction for their excellent thermal insulation properties, structural strength, and versatility.

2. EPS sandwich panel machines are available in various configurations and capacities to accommodate different production requirements. They are often equipped with automation and computerized PLC controls to improve efficiency, accuracy, and consistency in panel production.

3. EPS Sandwich Panel Production Line is a manufacturing process that creates insulated panels by combining metal sheets with expanded polystyrene (EPS) foam as the core. The line involves feeding metal coils, forming them into panels, applying EPS foam, curing, and assembling the final product. Making lighter, stronger, and more energy-efficient structures with this innovative machine. It creates EPS sandwich panels, ideal for walls, roofs, and more, using expanded polystyrene for insulation function.

4. Key Components Of EPS Sandwich Panel Production Line:

Metal coil uncoiler+Roll forming machine+EPS foam applicator+Curing oven+Panel assembly unit+Cutting and finishing equipment

The production Process:

1. Metal sheet preparation: Uncoiling metal coils and forming them into the desired shape for the panel’s outer layers.

2. EPS foam application: Apply a precise amount of expanded polystyrene (EPS) foam to one of the metal sheets.

3. Curing: Allowing the EPS foam to harden and set.

4. Panel assembly: Combining the second metal sheet with the EPS core to form the complete sandwich panel.

5. Finishing: Cutting the panel to the required size and potentially adding additional layers or coatings.

Technical Data

| No. | Item | Unit | RF-CP | RF-ZP |

| 1 | Production speed | m/min | 5-10 | 4-8 |

| 2 | Steel thickness | mm | 2.5 | 2.0-3.0 |

| 3 | Total power | KW | 12 | 18 |

Advantages

Cost-effective: EPS is a lightweight and affordable material, and the panels can be produced quickly and efficiently.

Energy-saving: The EPS core provides excellent insulation, which can help to reduce heating and cooling costs.

Durable: EPS panels are resistant to moisture, mold, and pests. They can also withstand strong winds and earthquakes.

Versatile: EPS panels can be used for a variety of applications, including walls, roofs, floors, and partitions. They can also be cut and shaped to fit any design.

The overall performance of the EPS sandwich panel is good and economic, such as its quake-proof and wind resistance and properties are much better than other wall materials. Light in weight. The EPS sandwich panel reduced the base load of the beam crossing section on the frame structure, and the 3d EPS blocks increased the usable floor area of the building, in addition, the EPS sandwich wall panel decreased the total cost. These panels offer advantages like excellent insulation, soundproofing, and structural strength, making them popular in modern construction.

Function And Application

EPS sandwich panel machine used to produce lightweight, prefabricated building panels consisting of a core of expandable polystyrene (EPS) sandwiched between two welded wire mesh faces.EPS sandwich panel is a insulation product, mainly used as internal and external walls in the construction industry. These panels are typically used in construction as insulation and structural components.

Company Introduction

Hangzhou Minglong Technology Co.,Ltd is a company located in We are dedicated to offering customers EPS machine, EPP machine. With the constant pursuit of the harmonious development between individual, enterprise and society, our company operates integrity management and seeks excellence and innovation, so as to develop continuously. Moreover, we practice our corporate culture value of 'practical and diligent, positive and motivated, beneficial and win-win'. Based on the scientific and rigorous management system, our company fostered a team of outstanding talents who dare to struggle and challenge. Minglong has been engaged in the production of EPS machine, EPP machine for many years and has accumulated rich industry experience. We have the ability to provide comprehensive and quality solutions according to actual situations and needs of different customers.

Our products are of excellent quality and favorable price, please feel free to contact us for quotation!