Newest Eps Sandwich Panel Machine Price List

Characteristics

1. This machine use for producing the shape forming packing products and some construction products, and it applies computer to control the whole process automatically, low voltage and high efficiency, fast forming, saving energy and big capacity.

2. It use advanced vacuum, condenser, and hydraulic system, different kind of heating, feeding and cooling. It can install the small and big mold.

3.There are four kinds of operating mode (Automatic, Semi-automatic, Middle-startup and Manual operation)with safe-guard protective device to ensure safe operation. Perfect failure self-diagnosing and overloading protection system, which keep machine safe and steady working.

4..Most of the main components are of world-famous brands, with reliable performance, stable quality, long service life and low maintenance cost.

5. This machine can choose mechanical ejection mold mode or hydraulic ejection mold mode.

6. This machine has the fast installing mold system.

Technical Data

| ITEM | Unit | FAV1400 | FAV1750 | FAV2000 | |

| Mould Dimension | mm | 1400*1250 | 1750*1450 | 2000*1650 | |

| Max product | mm | 1250*1100*420 | 1600*1300*420 | 1850*1500*420 | |

| Stroke | mm | 150~1500 | 150~1500 | 150~1500 | |

| Steam | Entry | mm | 89/108 | 108 | 125 |

| Consumption | kg/cycle | 6~9 | 6~11 | 8~13 | |

| Pressure | Mpa | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 | |

| Cooling water | Entry | mm | 89/108 | 108 | 125 |

| Consumption | kg/cycle | 30~90 | 35~100 | 40~130 | |

| Pressure | Mpa | 0.4~0.6 | 0.4~0.6 | 0.4~0.6 | |

| Compressed Air | Entry | mm | 50/76 | 76 | 76/89 |

| Consumption | m3/cycle | 1.8 | 2 | 2.5 | |

| Pressure | Mpa | 0.5~0.7 | 0.5~0.7 | 0.5~0.7 | |

| Vaccum Pump Capacity | m3/h | 230 | 290 | 290 | |

| Cycle Time | s | 60-120 | 60-120 | 70-140 | |

| Connected Load/Power | kw | 12.5 | 16.5 | 16.5 | |

| Overall Dimension | mm | 5700*1920*3250 | 5700*2030*3450 | 5700*2240*3680 | |

| Machine Weight | kg | 6500 | 7500 | 9500 | |

Advantages

1. Fully automatic working by computer control system with PLC and color touch screen.

2.Fast working process and short cycle time, Saving energy and high efficiency working capacity.

3. Germany and Japan proportional valves, meters, sensors, reduce valve, Europe pipe system and Schneider electronics to control steady steam and air pressure for steady working and making high quality products.

4. The machine has fast installing mold and auto locking mold system, and with foundation legs and electric crane, feeding oil system, single vacuum and condenser system.

5. The machine made by more thickness steel plates, bigger pipes &valves and stronger machine structure for high efficient working capacity and long working life.

6. Excellent machine design with easy installation,operation and maintenance, good welding and painting, beautiful appearance of the complete machine.

Detail Of Key Parts

Function And Application

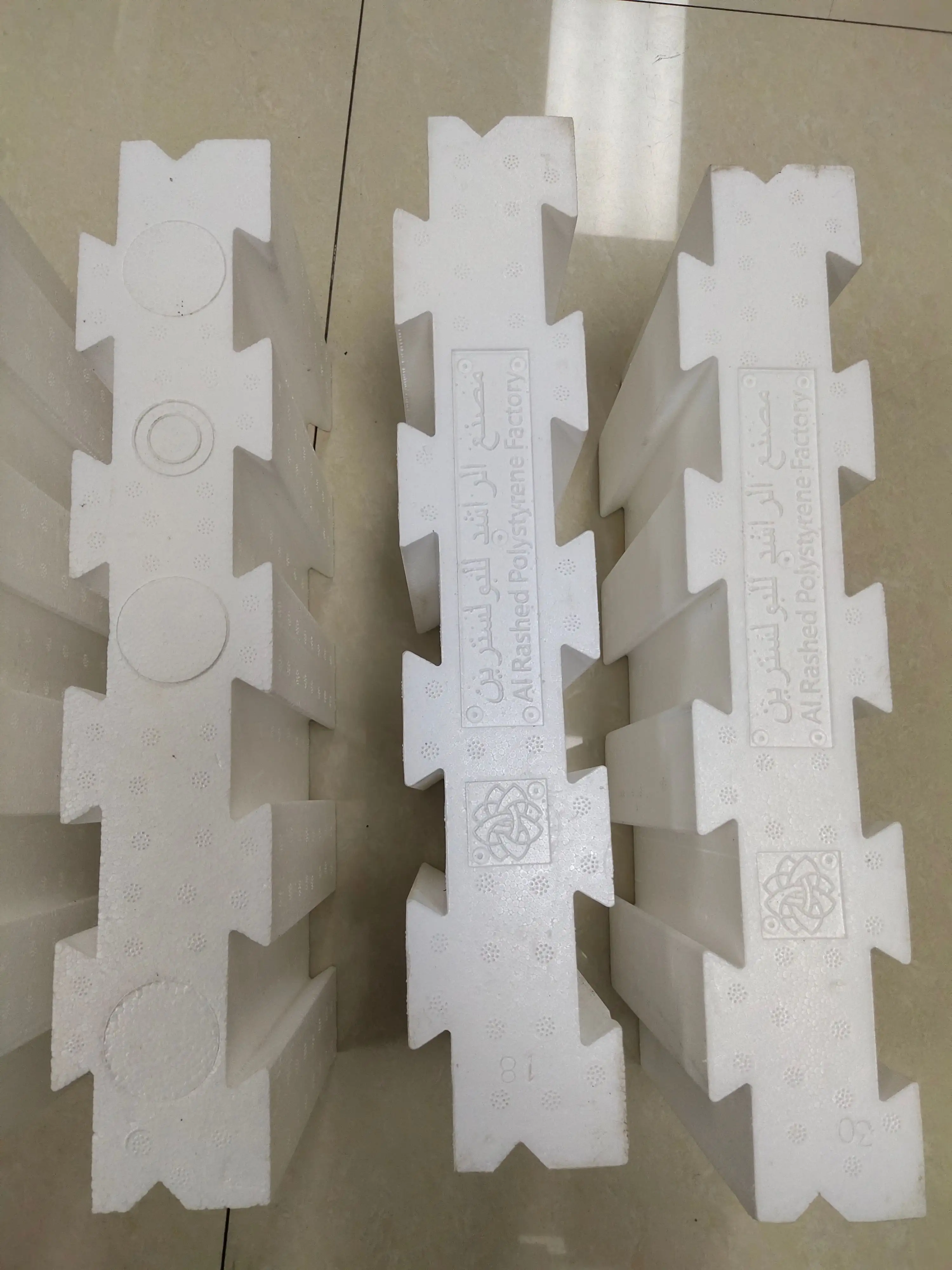

It used for running EPS molds to produce all kinds of packaging and insulation products such as seafood/fruit/vegetable/ice boxes, packing products, tools, decoration, cold storage, ICF constructions, cars and Appliances inner parts and so on.

Company Advantages

· Minglong eps sandwich panel machine is made with/of high quality and widely available raw materials.

· Our quality controllers responsible for making constant, small changes to keep the production working within defined parameters, ensuring the quality of the product.

· Our products are admired for their huge development prospects.

Company Features

· After years of stable development, Hangzhou Minglong Technology Co.,Ltd has become one of leading eps sandwich panel machine manufacturers.

· With rich R&D experience, Hangzhou Minglong Technology Co.,Ltd has done a good performance in launching new products.

· Flexibility, creativity, and continuous improvement are all the values our company treasured most. We are seeking ways to drive business improvement through improved flexibility in production procedures and product innovation.

Application of the Product

Minglong's eps sandwich panel machine can be used in multiple industries.

In addition to creating excellent EPS machine, EPP machine, Minglong is also able to provide comprehensive and reasonable solutions for customers.